消费者

SECTORS

Consumer

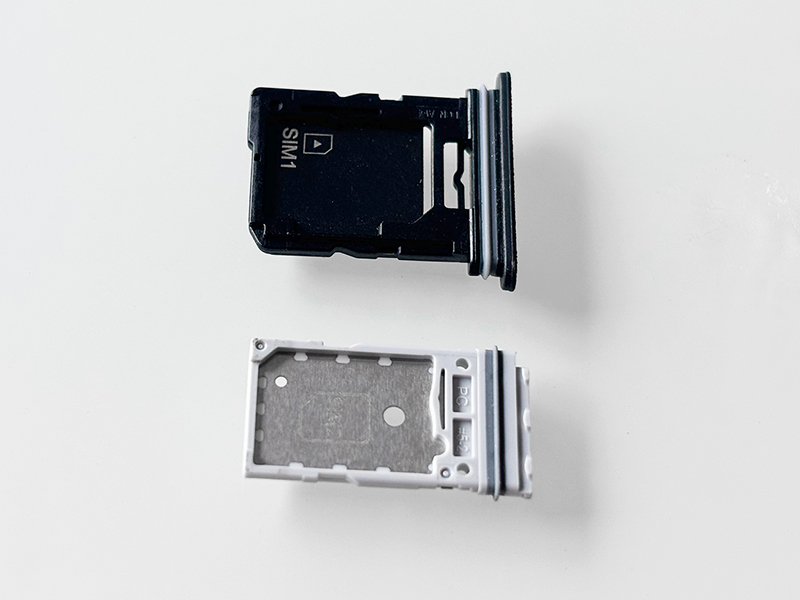

Multi-component injection molding and mold manufacturing are key technologies in the production of consumer products. Multi-material injection molding technology allows for the injection of multiple different materials into the same injection mold, enabling design diversity and functional versatility in products. This technique combines various materials such as plastics, metals, and rubbers to meet the requirements of different products. Mold manufacturing, on the other hand, forms the basis for producing multi-material injection molded products. By designing and machining molds, it ensures product quality and precision. Multi-material injection molding and mold manufacturing offer significant potential and opportunities for innovation and development in 3C&Smart Tech products, providing consumers with more diversity and functionality.

Consumer

We offer contract manufacturing services for our customers in the Consumer Product industry. We focus on decorative components and complex modular assemblies for the market including hair removal device, coffee makers, steam irons, action cameras, and blue-tooth audio headphones. Our wide range of services covers Design for Manufacturing (DFM) guidelines in product design, tooling & manufacturing feasibility, product development, in-house test & production precise injection mold making, molding, secondary operation & Automated Module Assembly.

Consumer

Let's start talking with us

我们的价值观

让我们以创新铸就未来

钜泰拥有一支经验丰富、技术娴熟的设计师、工程师和技术人员团队。高质量标准、有竞争力的价格、准时交货以及负责的售后服务是我们遵循的原则,也是与国内外客户建立相互信任和信息的保证。毕竟,钜泰核心价值始终在于——让我们的客户始终保持行业领先。

如果您有任何需要测试并推向市场的新产品设计,请随时与我们联系。我们将尽快回复您。